There is a lot of talk about battery electric vehicles, zero-emission vehicle mandates, and Greenhouse Gas Emission standards. At the same time, we should not overlook the fact that the internal combustion engine will be around for some time and simultaneously there are regulations which will affect the design and create changes to the diesel. One such regulation is what is referred to as EPA27, which will drive some significant changes to vehicle design and it is another example of new technology in the Messy Middle.

EPA27 goes into effect with model year 2027 vehicles and reduces the NOx from 0.2 g/b-hphr to 0.035 g/b-hphr. It also increases the useful life requirements. As a result of this extended emissions warranty period and the need to reduce NOx by 80+%, the cost of the vehicle is anticipated to increase. We don’t know the exact increase but there are some estimates that are putting the cost as high as by approximately $30,000. Much of this increase is probably because of the increased warranty life, however, some of it is the result of additional hardware and software. Light load idle fuel and DEF consumption are also likely to increase.

The why

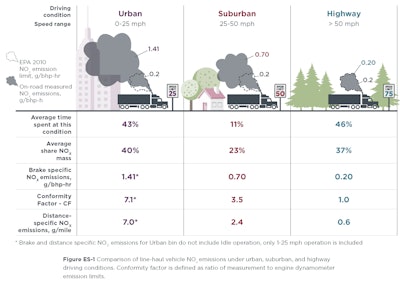

Today, most of the NOx is generated during light load conditions. Numerous studies support this fact. One such report by International Council on Clean Transportation is illustrated below. It states that for urban applications (speeds below 25 mph), the in-use NOx measured seven times higher than the EPA 2010 standard.

Selective Catalytic Reduction (SCR) is most efficient at high exhaust temperatures, typically between 250ºC to 350ºC. It works well at high loads and high speeds. In contrast, during light load operation, exhaust temperatures are below 200ºC.

The lower temperatures result in lower NOx conversion and hence the high in-use NOx as stated above.

The how

As we start to see EPA27 engines, it will be interesting to see the different types of technologies that will be used to meet these stringent emission standards. Each OEM is likely to utilize a different technology. However, all technologies will focus on raising the exhaust temperatures and adding additional catalysts.

There are different examples of the “Swiss-army-knife” blades that can be used to meet the regulations

• 48-volt mild hybrid and heater. This approach will consist of applying a resistive-like heater to the catalyst, thus generating heat and increasing the efficiency of the SCR. If an OEM pursues this approach, it is likely they also will introduce a mild hybrid which will consist of a 48-volt alternator to capture regenerative energy and store the energy in a small battery. This will minimize some of the losses to power the heater.

• Close coupled catalyst. A small catalyst could be added in the engine compartment downstream of the turbocharger. Since the catalyst is small and positioned next to the turbocharger, it will be able to begin the NOx conversion process at high temperatures thus improving the overall efficiency

• Dual dosing. This is complementary to the Close Coupled Catalyst in that a “hot” doser is positioned near the catalyst. This is a urea-based doser and performs a similar function as today’s SCR dosers, but it needs to be designed to meet the harsher environment of higher temperatures and vibration

• Cylinder deactivation. This feature deactivates cylinders, so the engine runs on fewer cylinders. The remaining cylinders run at higher brake mean effective pressure (BMEP) resulting in higher exhaust temperatures. These higher exhaust temperatures improve SCR NOx efficiency.

• Larger SCR volume. A larger SCR system provides more volume and catalyst surface area. This improves the interaction between the exhaust gases and the catalyst.

• Other miscellaneous features. Fast idle, variable valve actuation, heated urea, and other concepts are also likely to be implemented. All of these perform the same function of either providing more heat or greater NOx conversion efficiency.

Peterbilt, Cummins, and Volvo have made some announcements regarding their EPA27 (or CARB24 which is likely to be similar) plans. They will be utilizing the 48-volt mild hybrid and heater. Cummins indicates the heater will be rated at 5kW. Peterbilt indicates the overall volume of the SCR will increase.

It will be interesting to see what the other OEMs decide to pursue. Will it be similar to the above option, or will they pursue a close coupled catalyst and dual doser strategy? Also of interest will be how these new solutions affect DEF usage, idle fuel, etc.

EPA27 has not garnered as much excitement and interest as the regulations that are driving the use of battery electric and fuel cell vehicles. However, it will introduce significant changes to the trucking industry. These regulations will drive changes to the overall vehicle cost, warranty, and consumption of fuel and DEF.

This is just another example of the interesting times that the Messy Middle is introducing to our industry.