Note: Based on the convergence of technology in automation, connectivity and super infrastructure, the following story is the account of a fictional fleet terminal set in the coming decades. This story is based on reporting from CCJ’s Trucking’s Future Now package.

Stardate: The not-too-distant future

Location: Fleet terminal outside Des Moines, IA

Time: 0345 hours CST

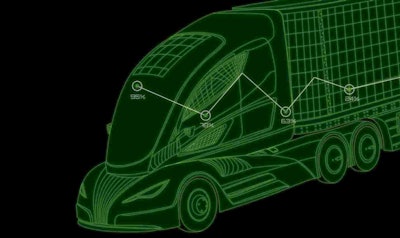

The truck itself looks similar to big rigs roaming the highways today. But it’s smaller, shorter and much lighter than its predecessors on the edge of the autonomous age. Because it almost never has a human behind the wheel, there’s no need for a sleeper compartment behind the cab. There’s also no need for a bunk, a fridge, a TV, storage cabinets, an infotainment center, APU or even a passenger seat for that matter. Although the prices are dropping rapidly, autonomous technology is still expensive. But deleting many of the comfort items necessary on human-controlled trucks mitigates the costs considerably.

This terminal runs 24/7, so in a few minutes a technician comes out to take charge of the truck. With a few sweeps of her smartphone, the tech downloads all the pertinent data for the vehicle: She notes that 5 weeks ago, in Guatemala, a fault code for a failing battery was flashed, which was replaced the next morning during a fueling stop at an American-owned truck stop chain just off the Pan-American Highway outside of San Jose, Costa Rica. Additionally, the tech notes that the Number 3 fuel injector needs to be replaced (diagnosed and signaled by the truck itself, the part arrived from the OEM two days ago) and an anti-churn sensor in the drive axle needs to be replaced as well. The truck flashed a low-coolant warning intermittently during its run south through the Peruvian desert on its run to Buenos Ares, Argentina. But predictive-diagnoses tracking indicates this is a false warning: This model truck and engine typically develop dry rot cracks on the hose connecting the overflow tank and the radiator with around 435,000 miles on the odometer. The tech has an automatically generated note on the maintenance order on her tablet computer from her fleet manager to change the hose out as a matter of course.